The working group for considering the petition to revoke the scrappage fee toured three automotive plants

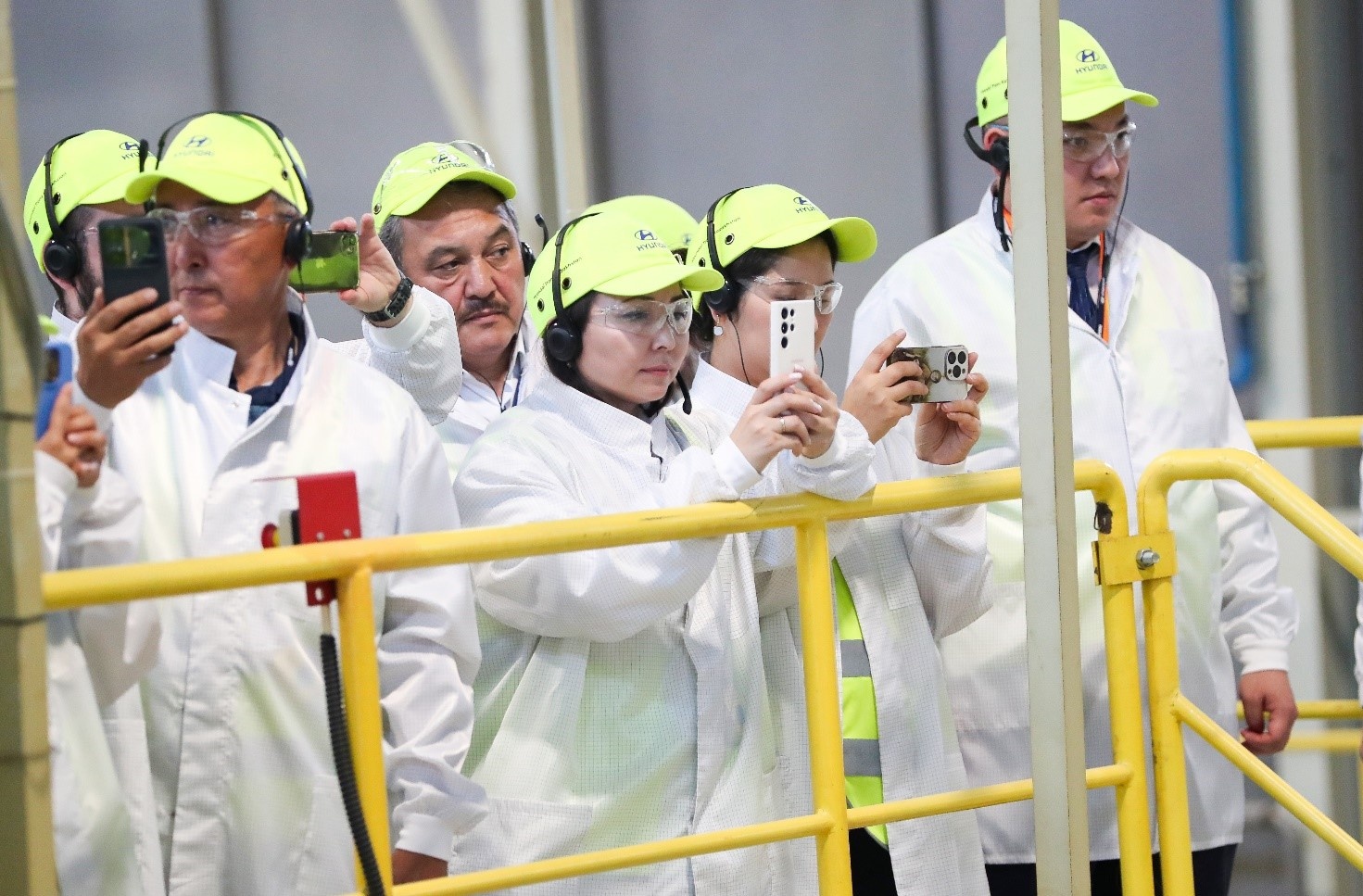

On June 18, the working group for considering the petition to revoke the scrappage fee toured the plants producing commercial vehicles and cars - Hyundai Trans Almaty and Hyundai Trans Kazakhstan and the Astana Motors Manufacturing Kazakhstan multi-brand plant currently under construction, which are owned by the Astana Motors group of companies.

Astana Motors broadcast the visit online on its own and independent Internet sites. Beknur Nesipbayev, CEO of Astana Motors, “We decided to use the working group’s visit for informational purposes. We have a long waiting list for plant tours and simply don’t have time to take in all the people. This broadcast will allow everyone interested in domestic production to take a video tour along with the working group.”

The first to tour was the Hyundai Trans Almaty commercial vehicle plant. This is the first automobile manufacturing project of Astana Motors. The plant makes vehicles with a load capacity of 1.5 to 15 tons based on the Hyundai and FOTON chassis (flatbed trucks, isothermal and industrial vans, refrigerators and various specialized body superstructures), as well as Golden Dragon buses of various models and their configurations from 10 to 18 m.

Adilbek Gayev, Director of Hyundai Trans Almaty, “In accordance with the assumed obligations for localization and Kazakhstan content, we introduced welding and painting of bodies of passenger, commercial, and school buses, trucks, as well as the production of attachments. This year, we will further expand our list of models manufactured using the completely knocked down method, as we are expanding our production areas - the welding shop, the superstructure production shop, the paint shop, and the cataphoresis shop for the launch of the Hyundai Porter model into production.”

The total cost of the project is 6.6 bln tenge. After the expansion, the plant area will be 19,400 sq. m, and up to 413 jobs will be created.

The next point of the tour was Hyundai Trans Kazakhstan, a full-cycle passenger car plant. It was presented by Beknur Nesipbayev, “The plant has been active since 2020. It makes eleven models of Hyundai passenger cars, such as the Accent, Elantra, Santa Fe, Sonata, Tucson, Bayon, i30, i20, Palisade, Staria, Custin, as well as the Genesis launched in pilot production. Now we are working on expanding our model range made using the CKD method. By the next year, we expect to increase the localization percentage by launching an auto component production cluster, where car seats, polyurethane mats, fenders, mudguards, and car multimedia systems will be produced with an output of 100,000 sets per year - to cover the needs of Hyundai Trans Kazakhstan and the KIA plant.

Hyundai Trans Kazakhstan plant includes welding, painting, assembly, plastic part painting shops and a car parts warehouse. Hyundai Trans Kazakhstan meets the requirements of Hyundai Motor Company and has certification documents from such well-known companies as VCA (UK), RDW (Netherlands) and TÜV Rheinland Korea, which certify world-class plants in Europe, the US, and Asia.

The project costs over 46 bln tenge in total, the plant has an area of 40,000 sq. m and about 1300 jobs created, and its production capacity is 50,000 units per year.

The working group also toured Astana Motors Manufacturing Kazakhstan, a multi-brand plant currently under construction. It will launch the production of Chery and Changan cars and Great Wall Motor’s Haval and Tank models as soon as the first quarter of 2025. The plant’s capacity is 90,000 cars per year.

Beknur Nesipbayev, “We see our potential in creating “full-cycle automotive industry.” Auto component production will attract other sectors to the automotive industry - from metalworking to petrochemicals. The automotive industry is not isolated: it drives all the production industries in the country, it is a game changer.”

At the end of the familiarization tour, a question and answer session was held for members of the working group and media representatives. It touched upon such matters as limit barriers for manufacturers and investors, allocation of scrappage fees, the role of Zhasyl Damu in scrappage fee distribution, and the upcoming public hearings on the petition for the revocation of the scrappage fee.

Zhomart Aliyev, Vice Minister of Ecology and Natural Resources of the Republic of Kazakhstan, “A certain public opinion has been formed, including due to the issue with manufacturers’ extended obligations and a certain information vacuum, we failed to give a detailed explanation, and here we may also be to blame. The funds from the scrappage fee are allocated only for the purposes specified in Article 388 of the Environmental Code. They include support for the automotive industry. However, it does not mean giving the money to automakers but exempting them from the scrappage fee. That is, if you import a foreign-made car to the country, you are charged the scrappage fee, if you manufacture a car, you are not charged the fee, and accordingly, the car price does not include the scrappage fee either. And automakers do not receive any money from the scrappage fee.”

The off-site meeting of the Working Group was attended by members of the Parliament of the Republic of Kazakhstan, vice ministers of industry and construction, ecology and natural resources, agriculture, representatives of the ministries of internal affairs, national economy, digital development, innovation and aerospace industry, the Kazakhstan Automobile Union, the Union of Industrial Investors of Kazakhstan, the Union of Independent Business of Kazakhstan. The initiators of the petition ignored the tour of Almaty automobile plants and the meeting of the working group.

The broadcast is available on:

YouTube: https://youtube.com/live/8JQTQHNlUZI?feature=share