Denis Kolomatsky, Hyundai Auto Kazakhstan: The Supplies Will Double in Just a Month

Hyundai Trans Kazakhstan will start supplying twice as many cars to the Kazakhstan market, which means another 25,000 new Hyundai vehicles by the end of the year.

The increased production is a result of negotiations between Hyundai Auto Kazakhstan, a subsidiary of Astana Motors (Kazakhstan), and Hyundai Motor Company (South Korea).

Director of official Hyundai Auto Kazakhstan distribution Mr. Denis Kolomatsky disclosed some details of the negotiations with the Hyundai headquarters, and revealed short-term plans of the domestic car manufacturing plant in Almaty.

− Denis Kolomatsky: In October 2020, Hyundai Trans Kazakhstan launched a CKD assembly line with welding and painting shops for Hyundai Accent. At that time, the plant produced seven Hyundai models in general – Accent, Creta, Tucson, Sonata, Elantra, Santa Fe, and Palisade that was introduced a bit later.

In the meantime, a pandemic crisis was on the rise in the world. Demand for vehicles fell in most countries, factories stopped their operations and went into lockdown. At the same time, the demand for gadgets, “smart appliances”, and medical equipment rose dramatically, therefore semiconductor and electronic microchip manufacturers refocused their activities on them. As a result, the world car industry was left without one of the most important elements in the modern world that are key to the operation of many vehicle systems. For instance, up to 3,000 microchips are used in the production of one vehicle.

The situation was greatly exacerbated by a logistics malfunction. We received components from South Korea via two routes – by sea through Russia and through China. When China encountered the quarantine-related problems, the cargoes stood idle at the border for months. Most companies started to ship the goods via the route through Russia. Consequently, there was a collapse in Russia as the ports were overloaded, ships were idle in roadstead, and there was a shortage of containers and fitting platforms (a dedicated platform to transport large-capacity containers). The price for shipping one container surged from 3,500 to 12,500 US Dollars, component delivery time increased several-fold. While before the logistics crisis it took a month to deliver containers with components from South Korea to Almaty, during the pandemic the transit time increased to half a year.

At the same time, we observed a growing demand for our cars. In 2021, sales of new Hyundai cars in Kazakhstan totaled 22,736 units, which shows an increase by 27.33% versus 2020.

– How did you manage to manufacture vehicles with such a delay in components delivery?

We worked with the inventory stocks. It is extremely important for production to get the timing right and adhere to the schedule, so it is a must for us to purchase components 3–4 months in advance.

– Is the increase in sales related to the reduced-rate lending program?

– Undoubtedly, the new reduced-rate lending program has increased the number of those who are willing to buy a car. Notably, while 22,736 Hyundai cars were sold in 2021, approximately 3 % of them were purchased under the reduced-rate lending program. According to our forecasts, this new program may increase this figure by about 10 % of total sales.

It is worth noting that Hyundai is popular due to the high consumer characteristics of its cars – workability, quality, comfort, design. And the price is attractive, judging by the fact that the vast majority of Hyundai total sales are cars purchased for cash.

In the course of planning the construction of a Hyundai Trans Kazakhstan plant, we projected to reach full capacity of 45,000 vehicles in 2023. However, after a year of the enterprise operation, the demand for our cars greatly exceeded the supply, and we set ourselves a task of reaching the full production capacity as early as this year.

However, the supply of components was delayed. To minimize risks and curtail the dependence on supplies from one or two directions, particularly east and west, we started looking for opportunities for component supplies from other plants of Hyundai Motor Company both in the southeast and in the west. Such alternatives could be supplies of components from Hyundai plants in the Czech Republic, Turkey, China, and India.

In October 2021, we entered into negotiations with Hyundai Motor Company to expand the geography of supply routes and increase the quota for the supply of components to Kazakhstan.

– The discussion lasted for seven months, what prevented you from reaching an agreement sooner?

– The negotiations were held at the international level. They involved global changes in the activities of a number of large companies and enterprises. It is a time-consuming process to revise supplies for one or another country and reconfigure logistics that engaged several states, it required restructuring of many business and production processes. And just recently we have achieved the desired outcome. Our foreign partners have expressed confidence in us, revised their plans, and allocated additional resources so that we could produce more cars for our clients.

Thus, I can now safely say that this year Hyundai Trans Kazakhstan is going to reach its full production capacity. In 2021, the plant produced about two thousand cars a month. Year-to-date, we have supplied the Kazakhstan market with more than nine thousand vehicles. The plan for May is more than two thousand vehicles, for June − about three thousand vehicles, and starting July Hyundai Trans Kazakhstan will produce four thousand cars each month for Kazakhstan.

Total for the year is more than 37 thousand cars for the domestic market inclusive of 7−10 thousand vehicles manufactured by the CKD assembly method and represented by Hyundai Accent and Hyundai Tucson. By the way, looking ahead, our strategic goal is to increase the volume of CKD-assembled cars and, in parallel, to establish the manufacture of automotive components at our own plant, which we are planning to build in Almaty.

– Are you somehow affected by the sanctions imposed on Russia?

– Of course we are. Due to the geopolitical situation, we are experiencing problems with supplies of some components from the Hyundai plant in St. Petersburg for Accent and Creta. Thanks to new arrangements with Hyundai Motor Company to increase the quota for components for Kazakhstan and open additional routes, we feel confident and, moreover, continue to expand the model range. In February this year, Hyundai Trans Kazakhstan has launched the production of a Staria minivan and in June the plant is starting the manufacture of a Hyundai Bayon SUV and a Hyundai i30 passenger car.

We have also reconsidered the route for Accent components supplies – we have already received first batches of components from Hyundai plants in China, India and South Korea.

– The prospects are encouraging. However, at the moment buyers are saying that there are no vehicles in the car centers, and no one wants to wait and miss the opportunity of attractive reduced-rate lending terms. What shall we do?

– I recommend the following game plan. First of all, you need to decide which model you would like to buy. Then, you should visit an official Hyundai dealership, which are located in almost every city or town. Professionals in the dealerships will help you choose the configuration and color of the car, will help you find the car you are willing to buy. It is possible that a similar car has already been produced at our plant and it is being prepared for delivery to the autocenter – then, you should book the car. If the car you like is not available, then you are going to be put in an electronic queue.

No plant in the world produces the entire range of models at the same time with all the variety of configurations and colors, as it is technically impossible and impractical. The manufacturing process takes time and the enterprise produces vehicles in batches according to a plan drawn up based on orders received from the dealers that prepare their orders with due account of customer requests. Therefore, we produce models, configurations and colors most popular at any given period of time. So, if your car is not yet available in the autocenter and it has not been produced yet, you will have to wait for a while. Currently, the waiting period for a car is from two to two and a half months. In the near future, with the increase in production at our plant, the waiting time will be significantly reduced.

Out of 25 thousand vehicles to be produced by the end of the year, 20 thousand may be purchased under the reduced-rate auto lending program. These are the best-selling models, which value does not exceed KZT 15 million. The main conditions of the 2022 lending program: nominal interest rate – 4 %, amount of lending – maximum KZT 10 million, vehicle value – maximum KZT 15 million, lending period – up to 7 years, down payment – from 0 %.

– It would be good to sort out the confusion in the car queues. According to the social media, the most “nimble ones” reserved a place in a queue at several dealerships simultaneously. Does that mean they are going to get several cars?

– To date, there are 21 Hyundai dealerships. Each dealership maintains its own customer queue. Within a dealership, this is a single queue for everyone, regardless of whether you buy a car for cash, through a discounted or other financial program. We value all our clients equally, and our dealers give out cars as available on a first-come, first-served basis. In the end, this is a single consolidated queue that we – the official Hyundai distributor in Kazakhstan – see and supervise. We are not entitled to limit a consumer in their choice of a particular dealership, and since each center has its own queue, the consumer can register with several ones at the same time. But having received a bill to pay for the car at one of them, the consumer loses his/her queue at other dealerships.

A disappointing forecast for the so-called “resellers”.

I would say this is the end. As soon as we double the supply of vehicles to the market, “resellers” will be out of work at least with regard to our brand. Resellers thrive in times of shortage – where there is high demand for a product and short supply on the market, then you are sure to encounter plenty of those who want to make money on it.

In a couple of months, resellers will realize that their “business” is losing its meaning. That is why we do not recommend buying a car from private individuals paying extra for new cars that you will be able to buy in two or three months in the dealerships at the official price, legally clean and with a warranty. An important advantage of buying a vehicle at the official dealership is the safety and security of the deal as well as the after-sales service to the Hyundai standards.

Due to the shortage of vehicles I have mentioned earlier, the queue has slowed down in recent months, but as soon as next month dealers will be getting more cars and in July and August the frenzy will die down.

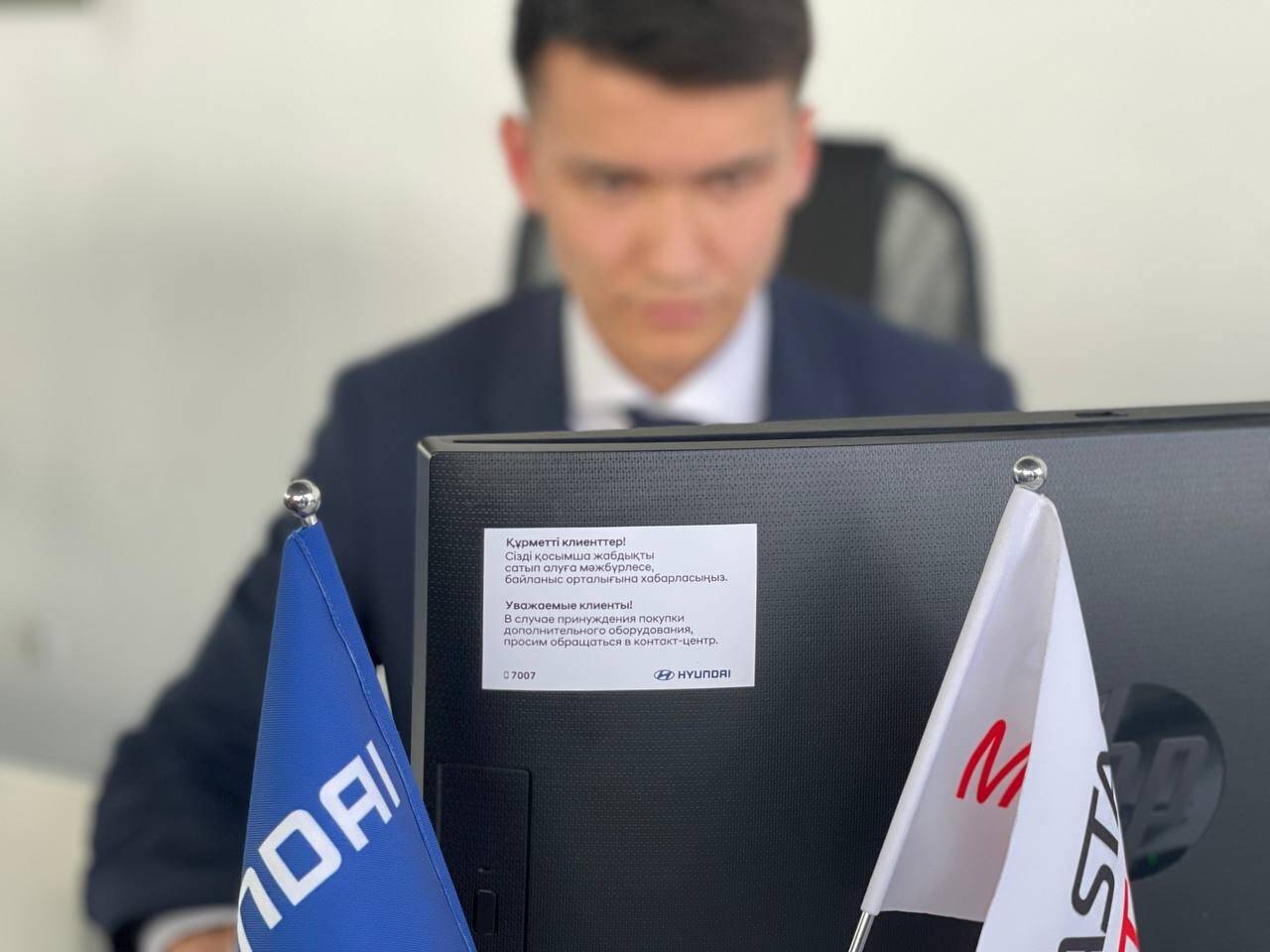

– How should one behave if a manager in the dealership “imposes” additional equipment for the car?

– Call the contact center 7007, it was established to consult and accept customer complaints including those about wrongdoings.

As an official Hyundai distributor, we work according to the principle that “the interests of our customer come first”. All of this is outlined in the dealer standards and customer interaction rules. Our task is to monitor the activity of dealers and in the event of any violation of certain rules, we take the toughest measures to violators, from fines to deprivation of a dealer status. No compromise is possible here. In case of repeated violations or in serious cases, we are entitled to terminate the dealership contract, and the dealer will lose its right to represent the Hyundai brand and sell our cars.

The more popular the brand is, the more customers we have, the more feedback and requests, and we strive to hold the bar high, to maintain high Hyundai standards in both production and service. Each day we dispatch new cars across the country from the Hyundai Trans Kazakhstan plant in Almaty, and in a month the supply will double. This is good news for people living in Kazakhstan and a breakthrough for our company and enterprise.

Source: informburo.kz